HOUSTON, TX, FebruAxiom Space, Inc., which is developing the world’s first commercial space station, has raised 130M in Series B funding. Axiom recently revealed the first-ever private astronaut ISS crew, launching in January 2022. The first two modules to be launched will each contain four crew quarters. International Space Station as early as 2024. The Axiom Station will be the cornerstone of a permanent human presence in space and a thriving network of commercial activity in LEO, driving new advances both on Earth and further out in space. Announcing astronaut crew for Axiom Mission 3, Ax3, set to launch to the International Space Station no earlier than January 2024 First-ever, all-European. The Axiom modules will be ready to detach and operate as a free-flying, next-generation commercial space station by 2028, operating into the future as the foundational layer of orbital infrastructure for microgravity research, manufacturing, and critical exploration life support testing, while also hosting astronauts from both the private and government spheres around the world.

While under construction off of the International Space Station’s Node 2 – also built by Thales Alenia Space – it will expand the usable and habitable volume of the ISS for the remainder of the orbiting lab’s lifespan. The Axiom Station will serve as humanity’s central hub for research, manufacturing, and commerce in low Earth orbit (LEO). After completion of primary structure component manufacture in Q2 2022, initial integration and testing operations will get underway for delivery of the first habitation module to Houston by early 2023, where Axiom will assemble, outfit, integrate, and prepare the complete spacecraft for launch. The primary structure passed its Preliminary Design Review and Critical Design Review in conjunction with Axiom Space and NASA. In fact, welding operations are already underway just 14 months after program launch. Engineers were able to identify the best technical solutions during the detailed design process, thus shortening the procurement and design phases. Thales Alenia Space called on the expertise built up over the last 40 years in building similar orbital infrastructures to implement this new technique. By applying this lower-temp welding process to such large modules, we can improve their reliability and mechanical properties in relation to the previous plasma welding method used on comparably sized habitation modules (e.g., nodes on the ISS, Columbus, MPLM).

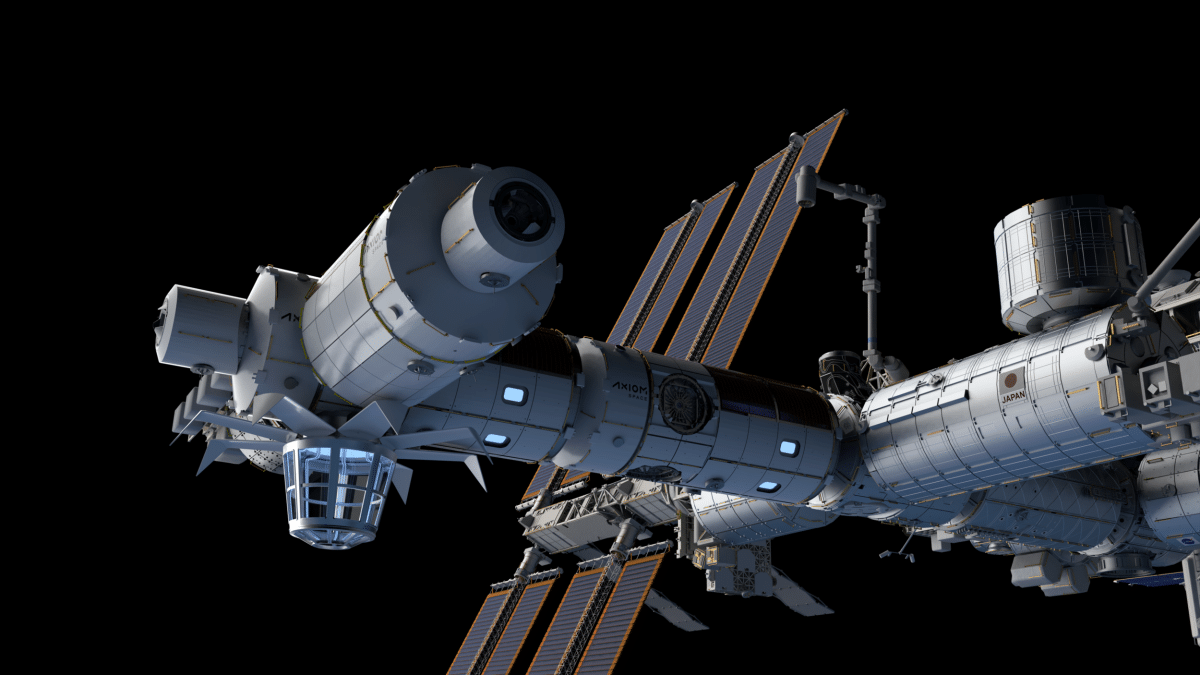

Axiom Space The first piece of the ISS, a Russian module named Zarya, launched to space in 1998. The welding of the pressurized module cone panels is the first step in the primary structure assembly process, leading to the production of a windowed pressurized module approximately 11 meters long and 4.2 meters in diameter at the widest part. An illustration of AxStation, the first private space station being designed and built by Axiom Space.

0 kommentar(er)

0 kommentar(er)